Tronrud Engineering, established in 1977, is committed to providing its customers with packaging and special-purpose machines that create added value. The company has around 150 employees at two sites in Norway. The team creates a wide variety of very different solutions ranging from automatic packaging machines all the way to computer-controlled looms, always with an eye to the company’s vision of “putting ideas into practice”. This is a perfect fit to our corporate culture of “inventing success together” and lays the best-possible foundation for a promising partnership.

Value engineeringat its finest

SFS as development partner

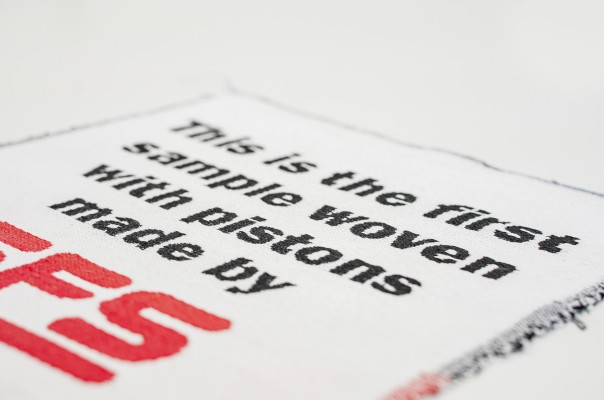

Tronrud Engineering needed a customer-specific valve assembly for its next generation of highly complex looms. In light of the fact that an average loom contains some 4,500 values and corresponding pistons, this assembly plays a key role in the looms’ pneumatic controls. SFS developed and produced this ready-to-install assembly in close collaboration with the customer.

High requirements met

Tronrud found itself faced with a challenge: the moisture absorbed by pneumatically driven pistons causes them to grow and this growth prevents movement. The problem occurs particularly in countries with high humidity levels. Specialists at the SFS Group found a raw material that absorbs no or only very little moisture. The element was then optimized during further follow-up operations with ongoing improvements made to the tolerance range. That enabled us to meet the high quality requirements without exception – and to do so with greater precision than the previous suppliers.

Project success engenders trust

SFS initially supplied Tronrud with the valve assembly. Because this project was successful, they also reached out to us for a solution to the piston problem and were impressed by the new, customer-specific piston. SFS delivered the first 40,000 units of the customer-specific assembly to Tronrud in 2021. The next year, in 2022, the number of units sold rose to 60,000. The successful product development collaboration prompted Tronrud Engineering to commission the SFS Group with the production of further assemblies in 2023.