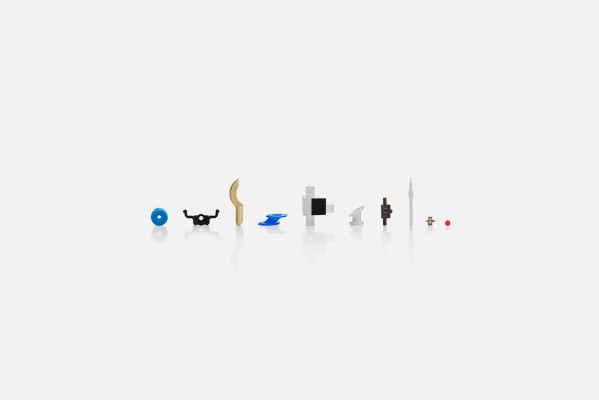

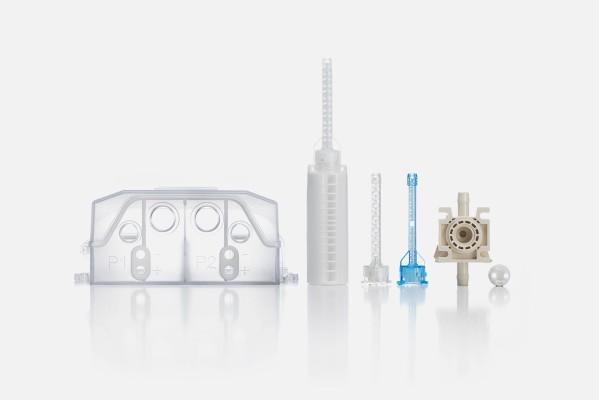

Custom-made for the purpose of use

All thermoplastics and elastomers, such as polyamide, polyethylene or acrylonitrile butadiene styrene, are fundamentally suitable for injection molding technology. Thanks to our specific application expertise for the processing of technical thermoplastics, high-performance plastics and thermoplastic elastomers we are in a position to define the best-possible customer-specific material for every task.