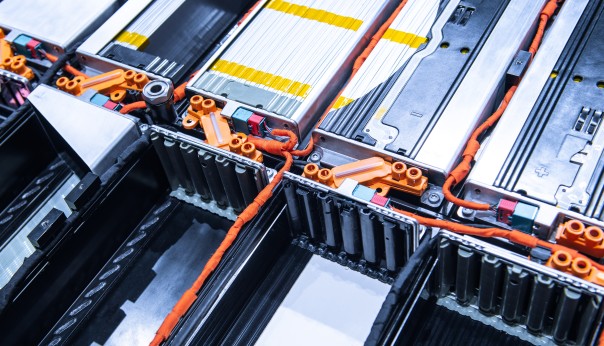

A leading global manufacturer of electronic components engaged SFS to develop high-precision, robust and cost-efficient components for a new series of batteries for EVs. The focus was on key parts for high voltage connections that require maximum reliability, safety, and optimal conductivity. These components were made using cold forming and in combination with the plastic injection molding technology – a targeted combination of the two technologies to turn functional, economical solutions into production-ready assembly methods.

Efficient development is key

Right from the beginning of the project, the SFS Group implemented a holistic development approach based on simultaneous engineering. This involved the customer’s development departments working in close collaboration with our internal teams. From the initial stages of product development, experts in engineering, material sciences and production worked hand in hand to fulfill the customer’s specific requirements. There are several benefits of simultaneous engineering: