Strive for technology change

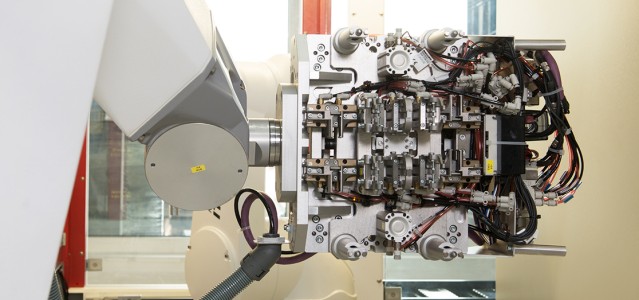

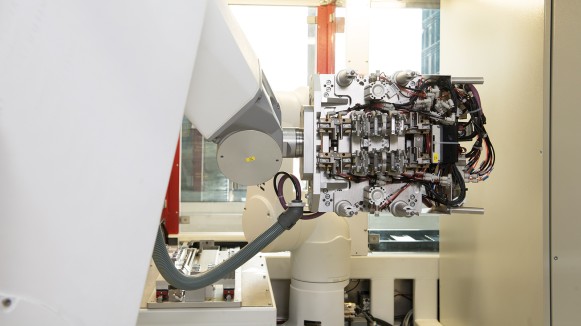

It was mid-2016 when this customer approached various partners in search of a supply solution for plastic injection moulded gear selector forks for midsize and premium vehicles for a major German car manufacturer. Because of the demanding end-customer requirements, STIWA Advanced Products were looking for an alternative technology option, from ultrasonic joining to injection moulding. The challenge, in addition to process matching, lay in the development and design of a manufacturing solution enabling all seven design variants of the selector forks to be automatically moulded.