Uniting core capabilities and winning synergies

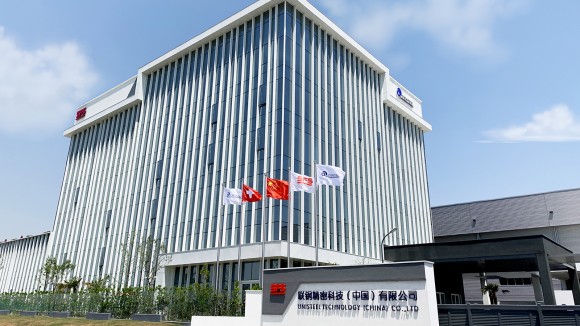

The new China plant, with its 90,000 m² of land space (78,000 m² build-up area) and in-house technologies, is ideally equipped to deliver products and solutions for the Electronics division while also realizing projects for other SFS divisions. Know-how and technology transfer projects enable cross-divisional partnerships. Joint exploitation of knowledge and resources will help to create innovative solutions and services as well as added value for our customers and for SFS.